The Difference Between Oxyfuel Cutting and Plasma Cutting and Choosing the Right One for Your Application

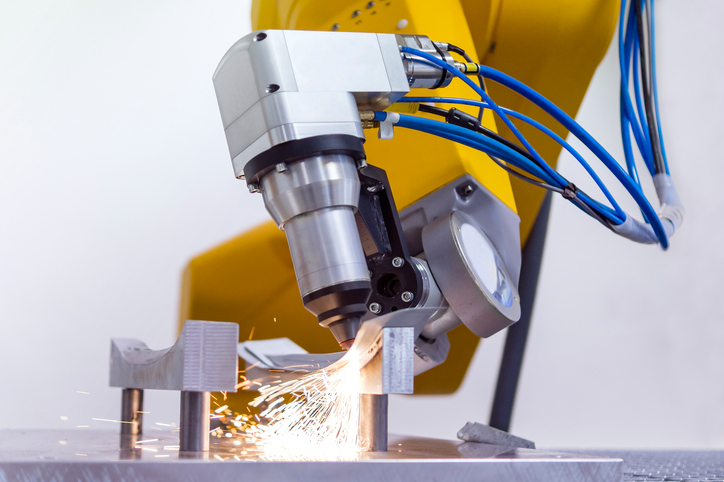

When it comes to automation in manufacturing, robotic cutting is a common practice. But when choosing between robotic oxyfuel cutting and robotic plasma cutting, many manufacturers find themselves at a crossroads. Both methods have their own strengths and weaknesses, and the best choice often depends on the specific requirements of your application. Plasma cutting works by passing an electric current through a gas, typically compressed air, which turns into a high-temperature plasma. This plasma is then forced through a nozzle at high speed, creating a focused, intense heat source that melts the material and allows for precise cuts. It's known for its speed and efficiency, especially with thinner materials. Oxyfuel cutting, on the other hand, uses a mixture of oxygen and a fuel gas, such as acetylene or propane, to generate a high-temperature flame. The material is first heated to its ignition point, and then a jet of pure oxygen is directed at the hot spot, causing the metal to oxidize and melt away. This method is particularly effective for thicker, ferrous metals like steel. Plasma cutting is ideal for thin to medium-thick non-ferrous metals like aluminum, copper, and stainless steel. It offers fast cutting speeds and clean edges, making it a popular choice in industries that require precision and efficiency. However, it’s less effective on thick metals and can struggle with materials that don’t conduct electricity well. Oxyfuel cutting excels in handling thick, iron-based materials. It provides excellent control and is often used in heavy industrial applications where large pieces need to be cut. However, it’s slower compared to plasma cutting and not suitable for thin or non-ferrous metals. The process also requires more setup time and careful handling of flammable gases. Both technologies have their place in modern manufacturing. The decision between them should be based on factors such as material type, thickness, desired cut quality, and production speed. In some cases, a combination of both may even be used to optimize performance. If you're unsure which method suits your needs best, consider consulting with a specialist who can evaluate your specific requirements and recommend the most efficient solution. Whether you're looking for speed, precision, or durability, there's a cutting method that fits your goals. For more insights into how Genesis Systems Group can help you choose the right robotic cutting technology for your business, explore our range of advanced oxyfuel and plasma cutting solutions today. 5 gallon water cooler cover,outdoor cooler covers,waterproof cooler cover,wine cooler cover Huaian Boshi Sports Products Co.,Ltd , https://www.cnboshisports.comUnderstanding the Difference Between Oxyfuel Cutting and Plasma Cutting and How to Choose the Right One for Your Needs

Key Advantages and Limitations of Each Method