The Difference Between Oxyfuel Cutting and Plasma Cutting and Choosing the Right One for Your Application

When it comes to automation in manufacturing, robotic cutting is a popular choice. However, manufacturers often face a key decision: should they use robotic oxyfuel cutting or robotic plasma cutting? Both methods have their own strengths and limitations, and the right choice depends on the specific needs of your application. Understanding the differences between these two cutting technologies can help you make an informed decision. Whether you're working with thick steel plates or thin aluminum sheets, knowing which method suits your project best is essential for efficiency, cost-effectiveness, and quality results. Plasma cutting uses an electric arc to ionize a gas, usually compressed air, creating a high-temperature plasma jet. This jet is then directed through a nozzle at the material, melting it and allowing for fast and precise cuts. The heat from the plasma is intense enough to cut through a variety of metals, making it ideal for thinner materials. Oxyfuel cutting, on the other hand, works by heating the metal with a flame made from a mixture of oxygen and fuel gas, such as acetylene. Once the metal reaches its ignition temperature, a high-pressure oxygen stream is introduced, causing a chemical reaction that burns through the material. This method is particularly effective for thicker, ferrous metals like steel. One of the biggest advantages of plasma cutting is speed. It’s known for being one of the fastest cutting methods available, especially when dealing with thin to medium thickness materials. It also offers good precision and is widely used in industries like fabrication and sheet metal work. However, plasma cutting has some limitations. It isn’t as effective for very thick materials, and it doesn't perform well with certain types of metals, such as stainless steel or non-ferrous materials. Additionally, the process can create a heat-affected zone that may affect the integrity of the cut edge. Oxyfuel cutting, while slower than plasma, is highly effective for cutting thick steel plates. It provides clean, accurate cuts and is often preferred in heavy industrial applications. It's also more cost-effective for large-scale operations where speed isn't the top priority. On the downside, oxyfuel cutting requires more setup time and is less efficient for thin materials. The cutting process also tends to be slower, and the heat generated can cause warping in some cases. Both plasma and oxyfuel cutting have their place in modern manufacturing. The choice ultimately depends on factors such as material type, thickness, required precision, and production speed. In many cases, using both methods in different stages of production can yield the best results. If you're looking for reliable robotic cutting solutions, consider exploring advanced systems like those offered by Genesis Systems Group. Their expertise in both plasma and oxyfuel cutting ensures that you get the right tool for the job, no matter the complexity of your application. Huaian Boshi Sports Products Co.,Ltd , https://www.cnboshisports.comThe Difference Between Oxyfuel Cutting and Plasma Cutting and Choosing the Right One for Your Application

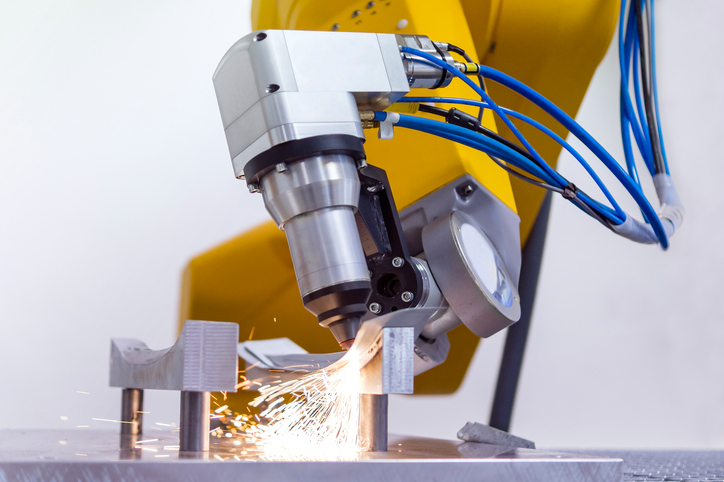

The Basics of Plasma Cutting and Oxyfuel Cutting

The Advantages and Disadvantages of Plasma Cutting and Oxyfuel Cutting