For a permanent-split capacitor type AC motor (commonly referred to as a capacitor start and run AC motor), a capacitor is essential for its proper functioning. Take a moment to relax and let me walk you through why this is so important.

Let’s start with a simple experiment. If you connect a single-phase permanent-split-capacitor type AC motor directly to a single-phase power supply without the capacitor, the motor probably won’t run unless you manually spin the shaft with an external force (this is much easier with an ungeared, round-shaft motor). This happens because we need at least two phases to generate a rotating magnetic field in the stator. That’s where the capacitor steps in.

What exactly does a capacitor do?

A capacitor, originally called a "condenser," is a passive electronic component that consists of at least two conductors (plates) separated by an insulator (dielectric). These conductors can be thin metal films, aluminum foil, or disks, while the insulator might be glass, ceramic, plastic film, air, or paper. When connected to a voltage source, a capacitor stores an electrical charge in the form of an electrostatic field between its conductors. In contrast, a battery uses chemicals to store an electrical charge and releases it slowly over time—possibly years. A capacitor, however, releases its energy much faster—within seconds or less. An everyday example is the flash from your camera.

**CAUTION**: Since a capacitor holds an electrical charge, avoid touching its terminals. If you must handle it, ensure the electrical charge is completely discharged first.

Now, what is the purpose of the capacitor in motors?

The capacitor’s role is to create a poly-phase power supply from a single-phase power supply. This enables the motor to:

1. Set the rotation direction.

2. Provide starting torque for the motor and increase torque during operation.

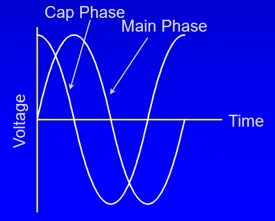

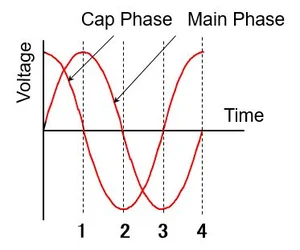

Oriental Motor’s AC motors are all permanent-split capacitor type (capacitor start and run) motors. These motors include a main winding and a secondary auxiliary winding. The capacitor is connected in series with the auxiliary winding, causing the current in the auxiliary winding to lag out of phase with the current in the main winding by 90 electrical degrees (a quarter of the entire cycle). As a result, we’ve effectively created a poly-phase power supply from a single-phase power supply.

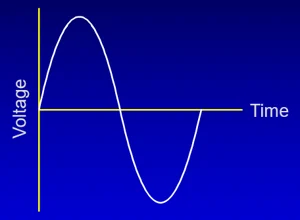

Here’s a visual comparison:

| Without a Capacitor | With a Capacitor |

|---------------------|------------------|

|  |  |

What kind of capacitor does Oriental Motor use?

Oriental Motor employs vapor-deposition electrode capacitors recognized by UL. This type of capacitor uses a metallized paper or plastic film as an element. It’s also known as a "self-healing (SH) capacitor." While many previous capacitors used paper elements, plastic film capacitors have become more popular in recent years due to their compact design.

**Rated Conduction Time**

The rated conduction time refers to the minimum design life of the capacitor when operated under rated conditions (load, voltage, temperature, and frequency). The standard life expectancy is 40,000 hours. At the end of its life, a capacitor might smoke or ignite. To avoid potential issues, we recommend replacing the capacitor after the rated conduction time.

**Safety Feature of Capacitor**

Some capacitors come equipped with a safety feature that allows them to safely and completely remove themselves from circuits in the event of a dielectric breakdown, preventing smoke and/or fire. Oriental Motor products use capacitors with UL recognized safety features that have passed the UL 810 requirement of a 10,000 A fault current test.

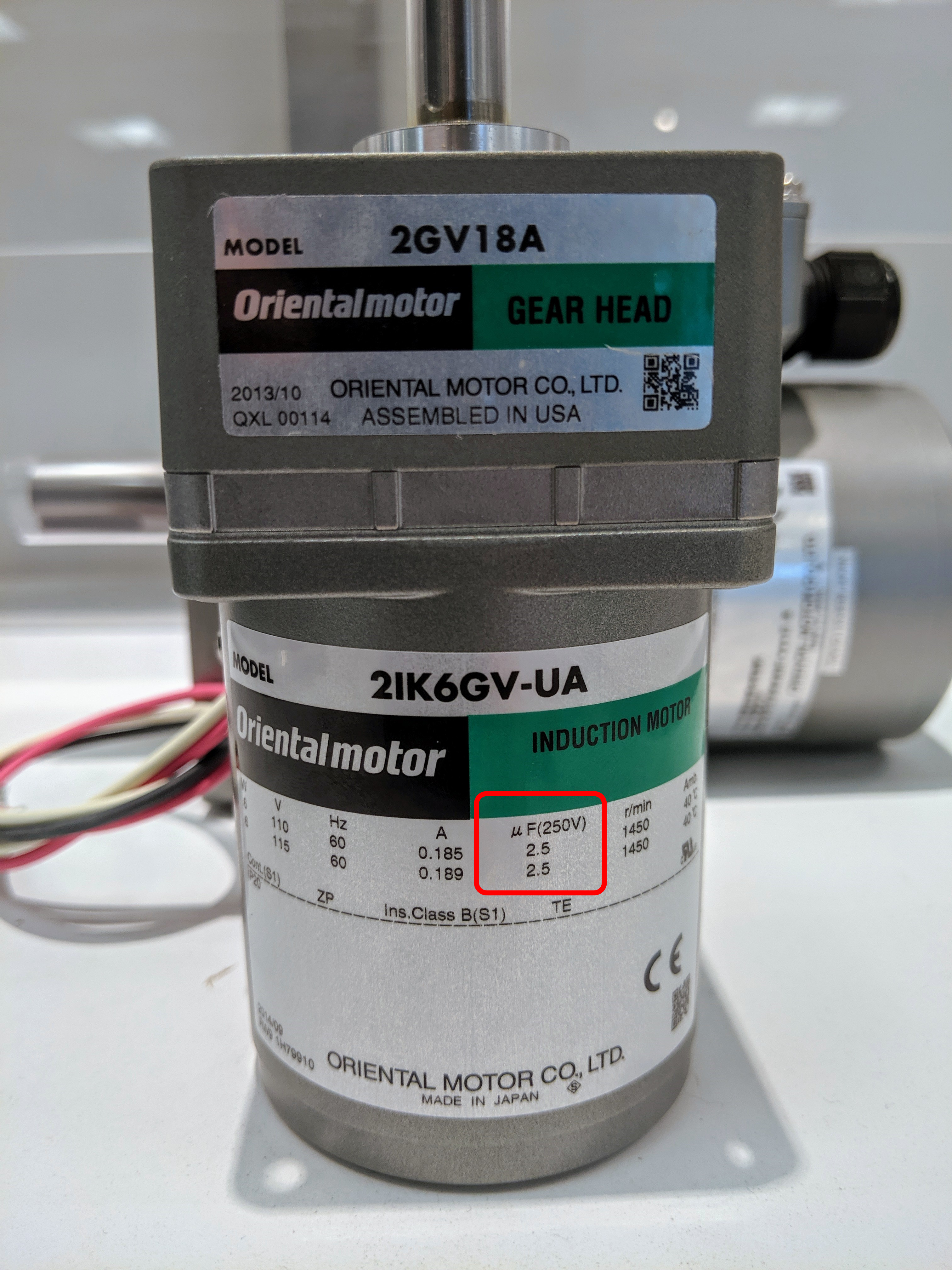

**How Are Capacitors Rated, and Why Is This Important?**

Capacitors are rated in terms of capacitance, working voltage, tolerance, leakage current, working temperature, equivalent series resistance, etc. For motor matching purposes, the two most crucial specifications are capacitance and working voltage. The voltage rating is usually about double the value of the motor’s rated input voltage in volts. There’s actually a formula to determine the capacitance for a motor, but we’ll save that for another discussion. For Oriental Motor’s compact AC motors, the unit of measurement for capacitance is "microfarad" (μF). These specifications are listed on both the motor label and the capacitor label.

| Motor Label with Recommended Capacitor | Capacitor Label |

|---------------------------------------|-----------------|

|  |  |

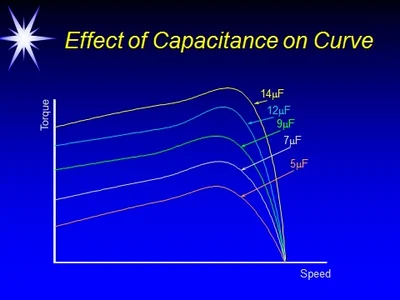

Using a capacitor with a different capacitance can increase motor vibration, heat generation, power consumption, torque variation, and unstable operation. If the capacitance is too high, motor torque will increase, but overheating and excessive vibration may occur. If the capacitance is too low, torque will drop. Using a capacitor exceeding the rated voltage may cause damage and the capacitor may smoke or ignite.

**Do I Need to Size the Right Capacitor for Oriental Motor’s AC Motors?**

No. Every single-phase AC motor from Oriental Motor comes with a dedicated capacitor that’s sized for the motor to operate at its highest efficiency and performance. No capacitor sizing is necessary.

**What Happens If I Use a Different Capacitor?**

To ensure the motor operates at its highest efficiency, always use the dedicated capacitor that comes with the motor. The dedicated capacitor creates a 90-degree electrical phase shift from the auxiliary (capacitor) phase to the main phase. Using the wrong capacitor can shift this away from the 90 degrees, leading to inefficiency, which can cause the motor to overheat with inconsistent torque or speed performance.

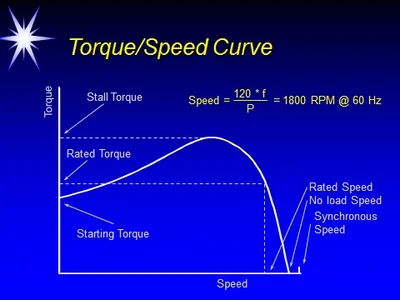

The dedicated capacitor is sized to have the motor produce this ideal torque/speed curve. Notice "Rated Speed" and "Rated Torque." This operating point (where these two intersect on the curve) is where the highest efficiency occurs. Every motor is designed for a rated load. Oversizing isn’t the best way to size AC motors.

| AC Motor Speed Torque Curve | Effect of Capacitance on AC Motor Speed Torque Curve |

|-----------------------------|-----------------------------------------------------|

|  |  |

A difference in the capacitance in the capacitor will affect both rated speed and rated torque as the operating point shifts away from its maximum efficiency. If you use two identical motors with vastly different capacitors, you’ll get vastly different results.

Once maximum efficiency is lost, heat generation increases for the motor. Excessive heat can degrade bearing grease and reduce the motor’s long-term lifespan. However, it’s good to know that if the winding temperature reaches 130°F, the thermal protection circuit inside the motor will trip and shut off the motor until it cools down.

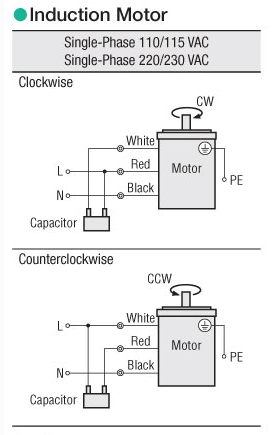

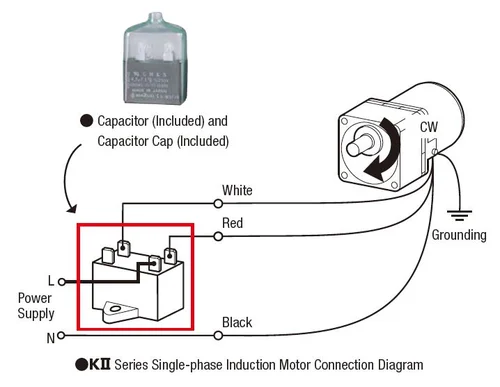

**How Do I Wire a Capacitor?**

For a 3-wire AC motor, connect the red and white lead wires to opposite terminals of the capacitor. Connect the black lead wire to the N (neutral) side of the power supply. For unidirectional operation, simply wire the L (live) side of the power supply to the terminal closest to either the red lead wire (for clockwise rotation) or the white lead wire (for counterclockwise rotation). HINT: The two closest terminals are joined internally. For bidirectional operation, use a single pole double throw (SPDT) switch between the live wire and the capacitor terminals to switch direction.

However, to switch the direction of an induction motor, you must wait until the motor comes to a complete stop. For reversible motors, the direction can be switched instantly.

| AC PSC 3 Wire Motor Wiring Diagram | AC PSC Motor Wiring with a Capacitor |

|------------------------------------|--------------------------------------|

|  |  |

Now that you understand the importance of capacitors, don’t lose them. If you do, use the motor label to identify the right capacitor to use. Stay tuned for more troubleshooting tips.

Related Resources:

- [Features and Types of Constant Speed Motors](http://bsg-i.nbxc.com/blog/46f36e7cbb3e77757761b7b4bdaced17.png)

- [Show & Tell: AC Induction Motors](http://bsg-i.nbxc.com/blog/1beaf45830cb7facd2b7caf90e6b6d27.png)

- [Show & Tell: AC Reversible Motors & AC Electromagnetic Brake Motors](http://bsg-i.nbxc.com/blog/68a0663b408849973e5f37c9d823e4a4.png)

- [How-To Videos: Wiring Different AC Motors](http://bsg-i.nbxc.com/blog/520546fed3b10b1c82c63892c1ef079a.png)

- [White Papers: AC Motor Technology](http://bsg-i.nbxc.com/blog/d78dc7e2c914ff92f5aac2299cdd130b.png)

Project And Construction

Refrigeration Project and Construction,Refrigeration Warehouse,Refrigeration Storage room Mfr Manufacturer and Supplier in China

Jiangsu Libang Electromechanical Equipment Co.,Ltd , https://www.liboncold.com