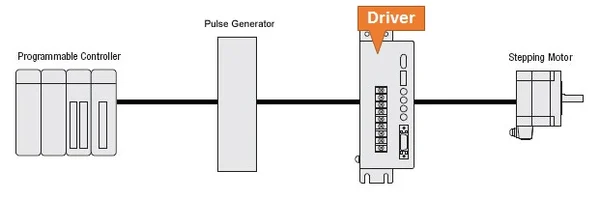

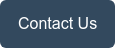

A driver is essential for any stepper motor system. It controls the motor's operation based on signals from the controller, sending current through the motor's phases and regulating torque and step resolution. As machines become more compact, finding space for drivers can be a challenge.

Standard Stepper Motor System Configuration

Oriental Motor understands the need for compact designs and has developed a range of mounting options for our stepper motor drivers to fit various machine layouts. Here are some common installation challenges and solutions:

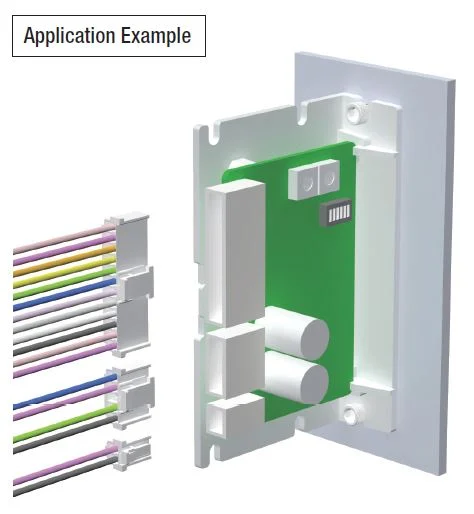

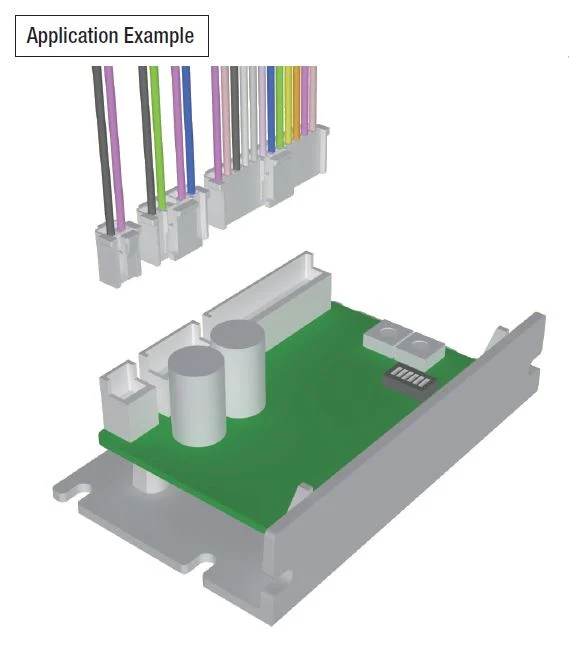

CHALLENGE 1  Mount a Driver Vertically with Horizontal ConnectionsÂ

SOLUTION  Use a Right Angle Driver with Mounting PlateÂ

These drivers have connectors that face outward (parallel to the board). They also support mating connectors, driver covers, and DIN rail brackets for flexible installation.

|

Right Angle Driver with Mounting Plate

Â

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'ed1ec589-c6d5-4787-91fd-98618b473177', {"useNewLoader":"true","region":"na1"}); Â hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'ed1ec589-c6d5-4787-91fd-98618b473177', {"useNewLoader":"true","region":"na1"}); Â

|

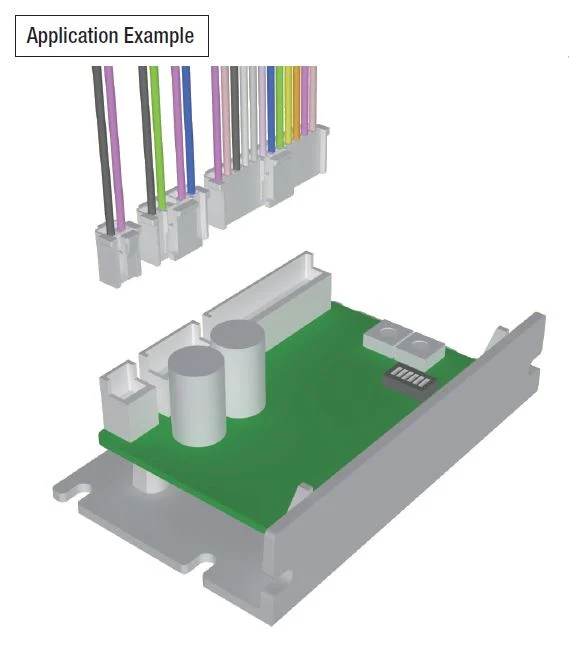

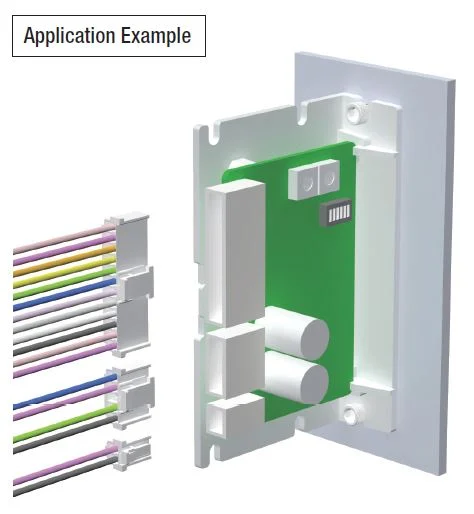

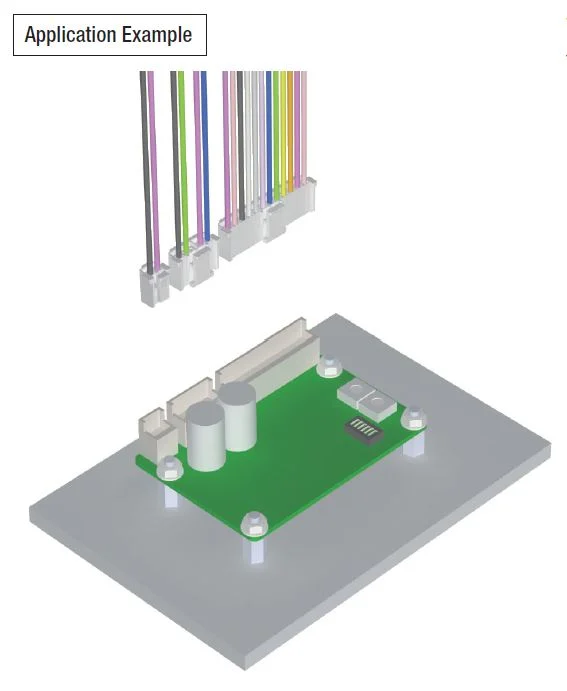

CHALLENGE 2  Mount a Driver Horizontally with Vertical ConnectionsÂ

SOLUTION  Use a Driver with Mounting PlateÂ

This type of driver allows the connectors to face upward (perpendicular to the board), making it ideal for horizontal installations. Mating connectors are included for easy setup.

|

Driver with Mounting Plate

Â

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fb0baaa1-43e5-4d2c-8163-19962c97d6f5', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fb0baaa1-43e5-4d2c-8163-19962c97d6f5', {"useNewLoader":"true","region":"na1"});

|

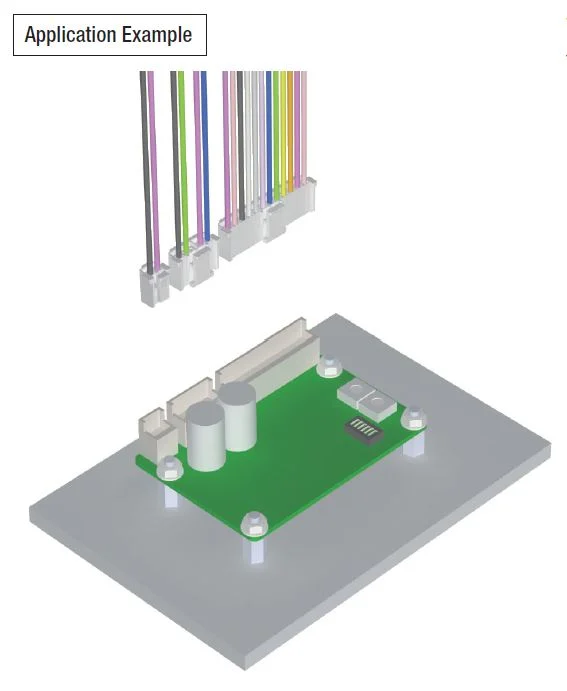

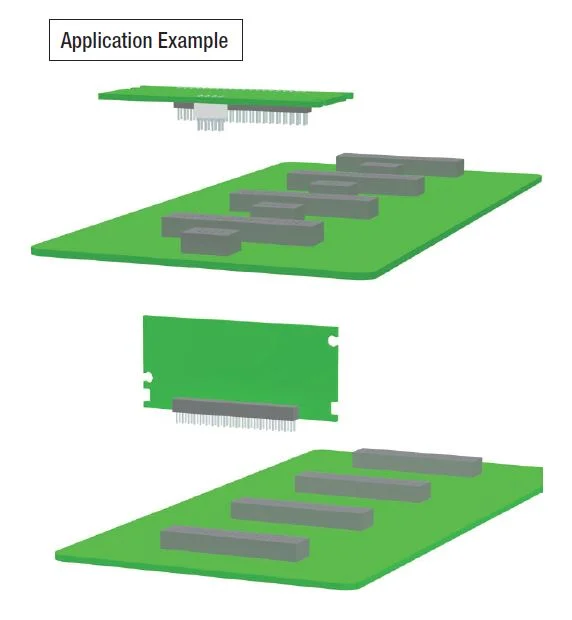

CHALLENGE 3  Mount a Driver Directly on a Metal PlateÂ

SOLUTION Use a Driver without Mounting PlateÂ

These drivers are designed for direct mounting on metal plates. With features like high-efficiency FETs, they eliminate the need for a heat sink, offering a compact and efficient solution.

|

Driver without Mounting Plate

Â

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3fab4bae-b91d-4a96-8341-81d41ffb0779', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3fab4bae-b91d-4a96-8341-81d41ffb0779', {"useNewLoader":"true","region":"na1"});

|

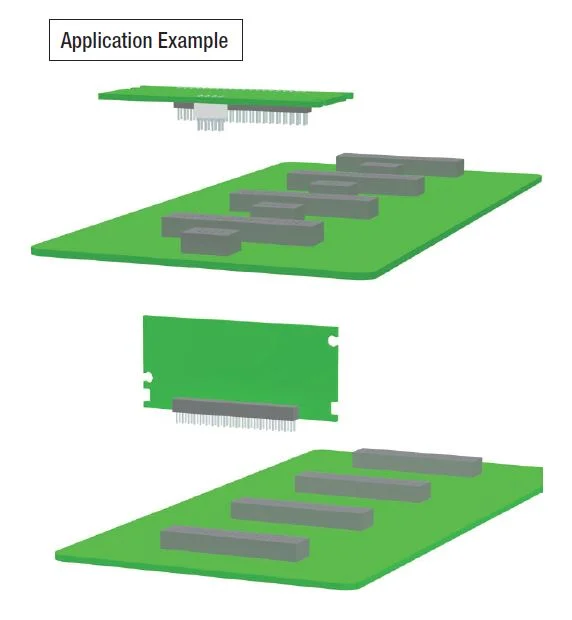

CHALLENGE 4  Mount a Driver Directly to a PCBÂ

SOLUTION Use S-Type DriversÂ

S-type drivers are perfect for custom PCB integrations. They can be mounted using pin sockets or directly soldered onto the board. Available in vertical and horizontal configurations, they support I/O or SPI communication.

|

S-Type Driver (available with SPI bus) hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '219bb3ef-0bea-42e0-96c2-40aedd2cc052', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '219bb3ef-0bea-42e0-96c2-40aedd2cc052', {"useNewLoader":"true","region":"na1"}); |

Oriental Motor offers CVD drivers for both 2-phase and 5-phase stepper motors. While 2-phase is more common, 5-phase motors provide smoother motion with reduced vibration and noise. Explore the benefits of CVD technology below:

- Advanced microstepping for smooth performance

- High-efficiency FETs for better power usage

- Digital current setting for precise control

- Vibration demonstration at resonant frequencies

- Multiple mounting options for flexibility

Watch this short video to see how CVD drivers enhance performance:

If you're unsure which driver is right for your application, contact us for expert guidance. We're here to help you choose the best solution for your needs.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e64b3511-e058-4331-988a-7b02387c7450', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e64b3511-e058-4331-988a-7b02387c7450', {"useNewLoader":"true","region":"na1"});

Woodfree Offset Paper

Uncoated Woodfree Offset Paper,Woodfree Offset Paper,Woodfree Paper,Woodfree Offset Printing Paper

Puyang Longfeng Paper Co.,Ltd. , https://www.lonfonpaper.com

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'ed1ec589-c6d5-4787-91fd-98618b473177', {"useNewLoader":"true","region":"na1"}); Â

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'ed1ec589-c6d5-4787-91fd-98618b473177', {"useNewLoader":"true","region":"na1"}); Â

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fb0baaa1-43e5-4d2c-8163-19962c97d6f5', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fb0baaa1-43e5-4d2c-8163-19962c97d6f5', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3fab4bae-b91d-4a96-8341-81d41ffb0779', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3fab4bae-b91d-4a96-8341-81d41ffb0779', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '219bb3ef-0bea-42e0-96c2-40aedd2cc052', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '219bb3ef-0bea-42e0-96c2-40aedd2cc052', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e64b3511-e058-4331-988a-7b02387c7450', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e64b3511-e058-4331-988a-7b02387c7450', {"useNewLoader":"true","region":"na1"});