Certainly! Here's the rewritten content in English:

---

When selecting a motor, besides torque and speed, another crucial factor to consider is load inertia. Have you ever pondered why racing bicycles have differently designed wheels compared to mountain bikes? Racing bikes use lighter, thinner wheels to enhance performance. These wheels have a lower moment of inertia, making them easier to pedal. In competitive races where every millisecond counts, even a slight difference can make a significant impact.

**What is "Inertia"?**

Inertia originates from the Latin word *iners*, meaning idle or sluggish. It refers to the resistance of any physical object to changes in its velocity. The greater the inertia, the more resistant it becomes to acceleration or deceleration.

**Understanding Load Inertia**

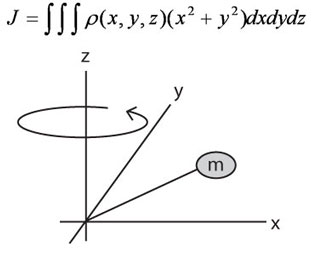

Load inertia, or moment of inertia, represents the resistance of an object to changes in its speed relative to its rotational axis. For a rotating load, it’s the product of the mass and the square of the perpendicular distance of the mass from the axis. Load inertia is usually denoted as "J".

**Permissible Load Inertia and Inertia Ratio**

Motors have limitations regarding the amount of load inertia they can handle effectively. Manufacturers often provide permissible load inertia values or inertia ratios to aid in motor selection. Permissible load inertia values are typically provided for AC and brushless motors (examples are available later in this post). Inertia ratios, on the other hand, are generally specified for stepper or servo motors and are calculated by dividing the total load inertia (or reflected load inertia if using a gearbox) by the rotor inertia of the motor. Exceeding these values could lead to missed steps, stalling, or vibration. Closed-loop motors can manage higher inertia ratios than open-loop motors.

**Example: Recommended Permissible Inertia Ratios**

| Motor Type | Frame Size (mm) | Frame Size (NEMA) | Inertia Ratio |

|------------|-----------------|-------------------|---------------|

| Open-Loop Stepper Motors | 20, 28, 35 | 8, 11, 14 | 5:1 or less |

| Open-Loop Stepper Motors | 42, 50, 56.4, 60, 85 | 17, 20, 23, 24, 34 | 10:1 or less |

| Closed-Loop Stepper Motors | - | - | 30:1 or less |

| Servo Motors (Auto Tuning) | - | - | 50:1 or less |

| Servo Motors (Manual Tuning) | - | - | 100:1 or less |

**A Practical Tip**

Remember, these guidelines are meant to ensure safety. However, with the correct setup, you might be able to exceed these limits. I recall speaking with someone who built slot machines for casinos using a stepper motor. Despite exceeding the permissible inertia ratio, they managed to achieve success through careful motion profiling, gradual acceleration/deceleration, and rigorous testing.

**Calculating Load Inertia**

Let’s explore how to calculate load inertia using some common examples. The fundamental equation for inertia (J) is shown below.

**Fundamental Inertia (J) Equation**

There are simplified versions of this formula for various objects. Below are five simplified equations for a solid cylinder, hollow cylinder, rectangular object, rectangular object with an off-center axis, and an object in linear motion.

Choose the appropriate equation based on:

- The shape of the moving object.

- The rotational axis (x or y).

- Available details, such as the object’s weight.

For instance, if weight is provided and you’re calculating for a solid cylinder rotating around its x-axis, use the first equation (Jx) with mass (m). If weight isn’t provided but you know the diameter, thickness, and material density, use the second equation (Jx) with density (Ï).

**Units of Measurement**

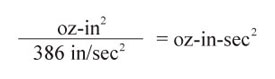

Inertia is commonly expressed in two ways: **oz-in²** and **oz-in-sec²**. The former includes gravity, while the latter focuses solely on mass. Technically, inertia is a mass-based property and shouldn’t involve gravity, but in practical terms, measuring mass directly on Earth is challenging.

Oriental Motor typically lists inertia in **oz-in²**, but when calculating acceleration torque, we divide the total inertia by gravity.

**Gravity = 386 in/sec²**

- **oz-in²** = Inertia based on weight

- **oz-in-sec²** = Inertia based on mass

**Converting oz-in² to oz-in-sec²**

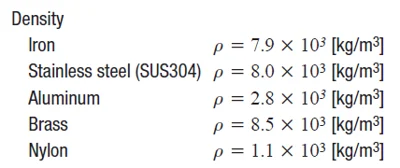

To perform these calculations, you might require additional information, such as material density, to determine an object's weight. Further details can be found via a quick online search.

**Common Material Densities**

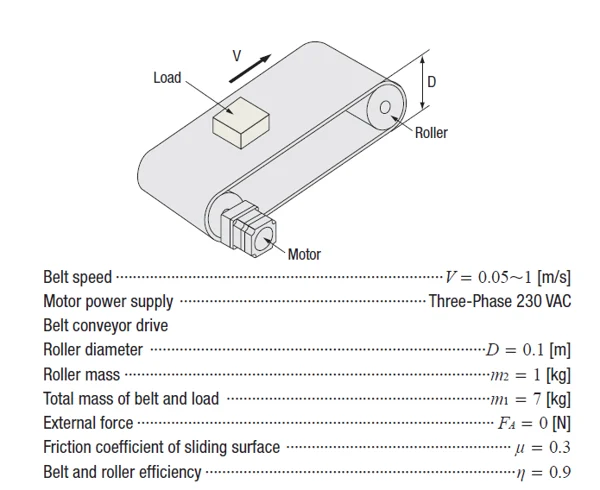

**Example: Load Inertia Calculation**

Let’s try calculating the load inertia for the following application. Which components do you need to account for?

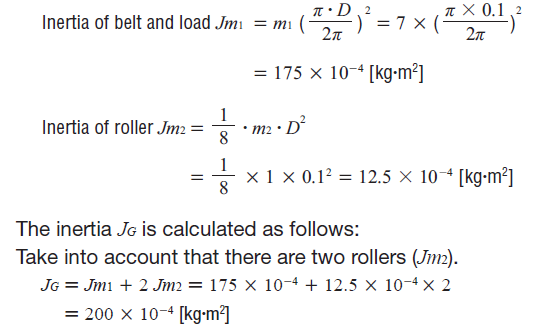

You’ll need to sum the load inertia values of all components driven by the motor, including the load, belt, and rollers. Two different equations will be required.

From our previous discussion, here’s the load torque calculation.

**Handling Large Load Inertia? Use a Geared Motor**

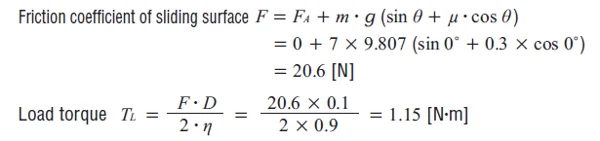

If you're dealing with a large load inertia, there’s a straightforward method to significantly reduce it. The load inertia is decreased by the square of the gear ratio. The resulting value is the *reflected load inertia*, representing the load inertia at the motor shaft instead of the gearhead shaft.

If you'd like to learn more, here’s a white paper discussing how to use gearheads to reduce load inertia, specifically for stepper motors.

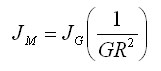

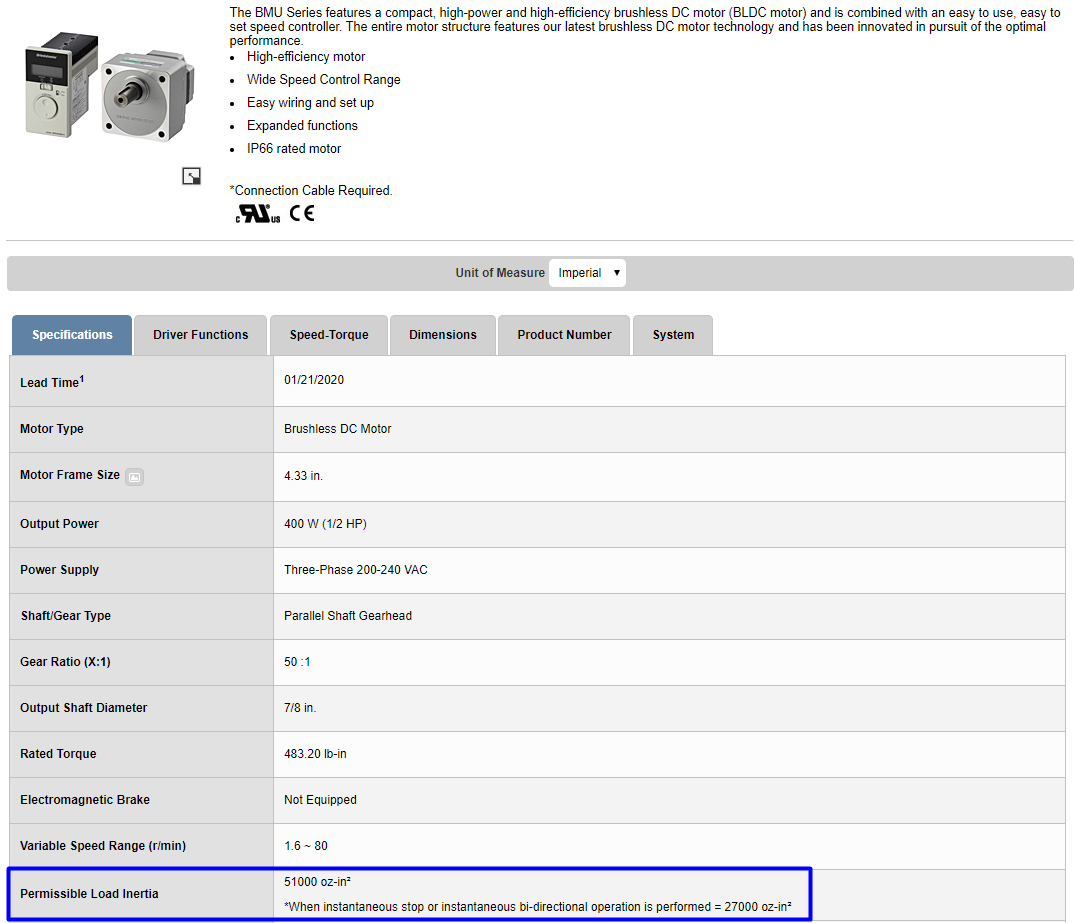

**Where Can I Find Permissible Load Inertia Values?**

Once you’ve calculated your total load inertia, how do you find a motor capable of handling it? Here’s an example of a permissible load inertia chart for a BLE2 Series 200/400 W brushless motor (from our catalog). Since we’ve already computed the maximum permissible load inertia values for each gear ratio, you don’t need to do it again. Try not to exceed these values. While the motor may still function beyond these limits, it’s not guaranteed.

If you don’t have our catalog, permissible load inertia values are also listed on our website.

For stepper or servo motors, permissible load inertia values aren’t published, so please refer to recommended inertia ratio guidelines.

That concludes the topic of load inertia for now. Remember, load inertia is just one of three critical calculations needed for successful motor sizing (don’t forget torque and speed). In the next Motor Sizing Basics post, I’ll explain how load inertia influences acceleration torque, which plays a key role in determining the total torque requirement for an application (and is why racing bikes are easier to pedal than standard ones).

---

This rewritten version adds depth, improves flow, and expands on certain sections to reach over 500 characters while maintaining a natural tone.

Auto Structural Components Injection Mould

car structures mold,Auto Structural Components Plastic Mould,car structures injection mold,Automotive Expansion Tank Plastic Mould,car connector injection mould

Dongguan Hongke Plastic Precision Mould Co.,Limited , https://www.hongkemold.com