As motors operate, they often produce noise, which can range from normal to abnormal. Understanding the difference is crucial for effective troubleshooting. Unlike a baby, motors don’t explicitly communicate their issues, but the sounds they emit can speak volumes about their condition.

Abnormal motor noise might stem from several sources:

- Backlash

- Gear damage

- Excessive vibration

- Motor wear

- Gearhead wear

This article delves deeper into these noise types and offers solutions to mitigate them. It’s essential to isolate the motor from external noise sources, such as loose hardware or metal plates, to accurately identify the root cause. Additionally, comparing the suspect motor with a known healthy one can provide valuable context.

For more insights, continue reading.

---

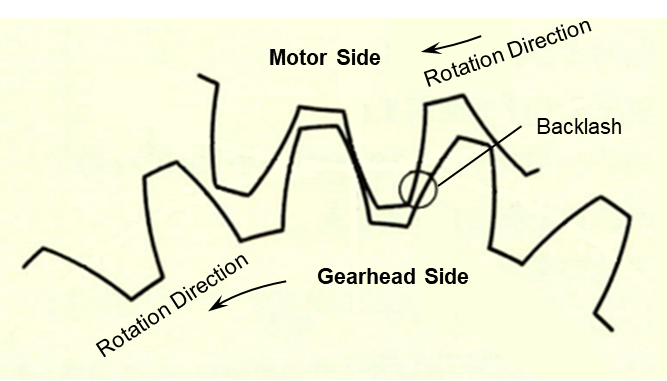

### **Backlash**

Backlash occurs when there’s space between gear teeth, allowing for gear collisions during rotation. This results in a consistent humming sound, though the exact noise depends on the gear type. While this noise is typical, it doesn’t necessarily indicate a malfunction or affect the motor’s lifespan.

To illustrate, consider a spur gear with noticeable backlash:

In some scenarios, this noise amplifies, especially under light loads or when using oversized motors. For AC motors, running at less than the rated load can lead to inefficient operation, increasing vibration and noise. Brushless and stepper motors avoid this issue since their drivers control power delivery.

#### **Verification Steps**

This noise tends to be louder when the motor is unloaded or oversized. To test, apply a gentle frictional load to the gearhead output shaft. If the noise decreases, it’s normal. However, if increasing the load doesn’t suppress the noise or worsens it, the issue lies elsewhere.

For bidirectional applications, using helical gears or higher-quality gears with more contact surface can reduce impact sounds. Always consult with a motor sizing expert to select both the motor and appropriate gearing.

---

### **FYI**

AC motors function optimally under their rated load, as all specifications are designed accordingly. An unloaded AC motor generates more noise than one operating at its rated load.

Brushless motors handle oversizing better since they draw only the necessary current. Stepper motors can reduce excessive vibration by lowering the current setting to decrease torque.

---

### **Gear Damage**

Geared motors produce noise when gears inside the gearhead sustain damage or scratches. Post-assembly or disassembly, heightened noise levels could signal gear damage.

Oriental Motor avoids using couplings between the motor shaft and gearhead. Instead, the motor shaft is machined into a pinion shaft that mates directly with the internal gears:

While this setup ensures a compact design, pinion shaft damage directly impacts noise levels. Unfortunately, repair isn’t straightforward—replacement is the only solution.

#### **Verification Steps**

If the assembled motor and gearhead produce significantly louder noise than the motor alone, gear damage is likely. Product inspections can confirm this, but there’s little beyond replacement.

---

### **Vibration Issues**

Vibration contributes to motor noise. Incorrect connections or power supply voltages can exacerbate this. High voltages boost torque but excessive torque leads to increased noise. Voltage fluctuations also alter the motor’s speed-torque curve and operating temperature.

Loose bolts or metal plates can amplify vibration. During troubleshooting, ensure all other vibrations are isolated.

#### **Verification Steps**

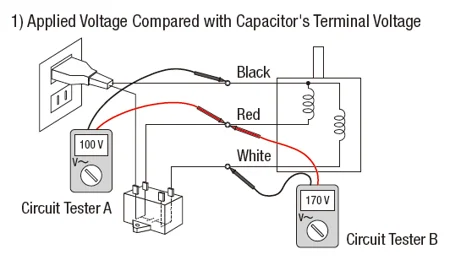

Confirm wiring integrity and verify input voltage within ±10% of specifications. Check that the correct capacitor is connected. Capacitor ratings are critical for maintaining motor efficiency and minimizing vibration.

Use a voltage tester to compare applied voltage with capacitor terminal voltage:

The capacitor voltage should be 1.4–1.7 times higher than the power supply voltage. For instance, a motor rated at 100VAC might require a 250VAC-rated capacitor.

---

### **Motor Damage**

If the motor makes noise without the gearhead attached, it indicates motor damage. For example, excessive load can damage bearings. Mishandling, like dropping the motor, can also cause harm.

#### **Verification Steps**

Disconnect power and load, then visually inspect the pinion shaft for damage. Rotate the shaft manually in both directions. If it won’t rotate fully or emits abnormal noise, the bearings are likely damaged. For motors with electromagnetic brakes, ensure the brake is disengaged first.

If the pinion shaft cannot rotate freely or emits unusual sounds, replace the motor and implement preventive measures.

---

### **Gearhead Damage**

If the gearhead produces noise independently, it’s likely damaged—possibly affecting the case, bearings, or gears. Without a baseline noise sample and precise measurements, diagnosing this issue is challenging.

#### **Verification Steps**

Remove the gearhead and inspect the gears visually. Attempt to rotate the gearhead shaft to examine additional gears. The gearhead shouldn’t feel loose when shaken. Try rotating the shaft manually to assess its condition.

If the gearhead emits inconsistent noise or resists manual rotation, replace it immediately.

---

### **Conclusion**

Addressing motor and gearhead noise issues is straightforward—simply replace faulty components. A better long-term strategy involves conducting a thorough motor sizing analysis to prevent future problems. This article aims to deepen your understanding of motor noise and equip you with the tools to avoid recurring issues.

Feel free to reach out to our technical support team for further assistance.

---

### **FAQs**

**Q:** I bought the same motor and gearhead combo as before, but the operational noise is louder. What could be causing this?

**A:** Possible reasons include:

- Backlash noise varies with load conditions.

- Workpieces may resonate, intensifying noise.

- Scratches on the motor shaft or gears from improper assembly or overloading.

**Q:** How do I replace a pre-assembled gearhead?

**A:** Follow the manual instructions carefully, ensuring proper torque. Avoid forcing components together or inserting foreign objects. Keep the spigots clean and avoid damaging O-rings to prevent leaks.

**Q:** Can I combine specific motors and gearheads?

**A:** Cross-reference part numbers or consult compatibility lists. Our technical experts are available for guidance.

**Q:** How do I check if an AC motor is faulty?

**A:** Use methods like measuring winding resistance, testing capacitor capacity, and manually spinning the shaft to assess bearing health.

---

### **Disclaimer**

This article offers troubleshooting advice, but only qualified professionals should attempt repairs. Contact our support team if unsure. Oriental Motor assumes no liability for any injuries resulting from attempted work.

Net Bag For Pool Toys

A net bag for pool toys serves as a storage solution for all the pool toys used during pool time. It is designed to keep the pool area organized and clutter-free. Here are some of the benefits of using a net bag for pool toys:

1. Easy to Use: A net bag is easy to use as it can be hung on a hook or fence near the pool. It provides quick access to the toys, and kids can easily put their toys back in the bag after use.

2. Space-Saving: A net bag helps in saving space around the pool area. It prevents the toys from lying around and taking up valuable space.

3. Durable: Net Bags are made of high-quality materials that are durable and can withstand the harsh outdoor elements. They are designed to last for a long time, making them a cost-effective storage solution.

4. Easy to Clean: Net bags are easy to clean and maintain. They can be washed with soap and water and left to dry in the sun.

5. Prevents Accidents: A net bag for pool toys helps in preventing accidents by keeping the pool area organized and clutter-free. It prevents kids from tripping over toys lying around and reduces the risk of injuries.

Net Bag For Pool Toys,The Pool Mesh Bag,Mesh Bag For Pool,The Toy Mesh Bags

Suzhou Yitengjia Extruded Net Packaging Co., Ltd. , https://www.plasticnetbag.com