Here, the density value in both Metric and English units refers to the mass per unit volume of Stainless Steel 316 material.

In metric terms, the density is 8 g/cc, meaning that one cubic centimeter of SS 316 weighs 8 grams. On the other hand, in English units, the density is 0.290 lb/in³, indicating that one cubic inch of SS 316 weighs 0.290 pounds.

These density values are critical when calculating the weight of stainless steel components.

Table of Contents

- Stainless Steel 316 Density

- AISI 316 Chemical Composition

- Stainless Steel 316 Mechanical Properties

- WNR 1.4401 Material Equivalent

- 316 SS Linear Coefficient of Thermal Expansion

- Thermal Conductivity of SS 1.4401

- INOX 316 Specific Heat

- Alloy 316 Magnetic Permeability

- Electrical Resistivity of SS 316

- Forging of SUS 316

- Machinability of X5CrNiMo17-12-2

- Weldability of UNS S31600

- 316 Stainless Steel Heat Treatment

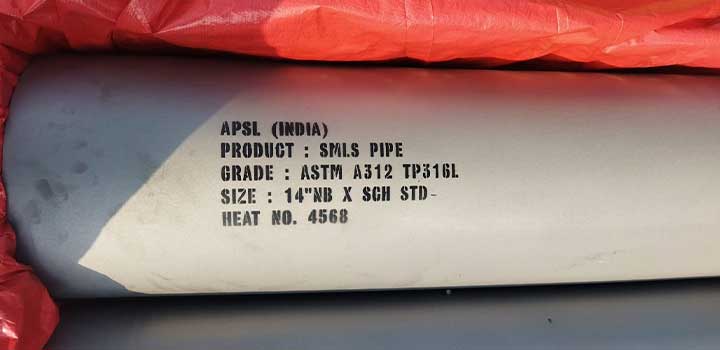

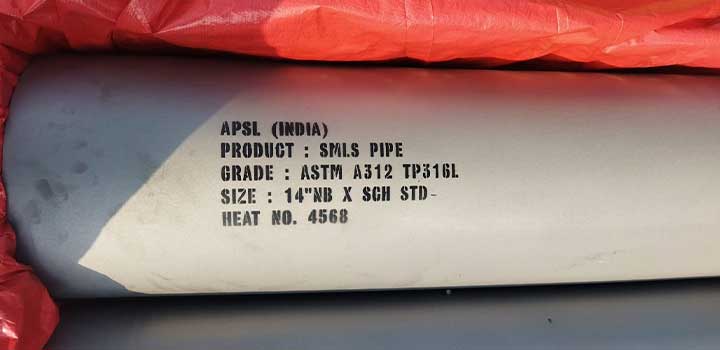

- ASTM Standards of EN 1.4401 Grade

- Environmental Properties of BS 316S31 Material

- Why You Should Know the Density of AISI 316 Grade

- Operating Temperature of WNR 1.4401

- Is the 316 SS Material Magnetic?

- Is the SS 1.4401 Material Polishable?

- Yield and Tensile Strength of INOX 316 Grade

- SS 316 VS 316L

Stainless Steel 316 Density

| Properties |

Metric |

English |

| Density |

8 g/cc |

0.290 lb/in³ |

AISI 316 is an austenitic grade with added molybdenum, refer to the chemical composition of 316 SS Grade.

The addition of molybdenum enhances its general corrosion and pitting resistance properties. It also provides excellent creep, tensile strength, and stress-to-rupture at high temperatures.

Due to these properties, AISI 316 is highly suitable for applications requiring resistance to high temperatures.

AISI 316 Chemical Composition

Stainless Steel 316 Mechanical Properties

| Grade |

Tensile Strength, Min. |

0.2% Yield Strength, Min. |

Elongation In 2†(50mm) |

Hardness, Max. |

| psi |

MPa |

psi |

MPa |

%, Min. |

Brinell |

RB |

| 316 |

75000 |

515 |

30000 |

205 |

40 |

217 |

95 |

WNR 1.4401 Material Equivalent

| EN (European Norms) |

AISI (American Iron and Steel Institute) |

UNS (Unified Numbering System) |

AFNOR |

| X2CrNiMo17-12-2 |

AISI 316L |

S31603 |

Z7ND 17.11.02 |

316 SS Linear Coefficient of Thermal Expansion

| Temperature Range |

Mean Coefficient of Thermal Expansion |

| °C |

°F |

cm/cm°C |

in/in/°F |

| 20-100 |

68-212 |

16.5·10-6 |

9.2·10-6 |

| 20-500 |

68-932 |

18.2·10-6 |

10.1·10-6 |

| 20-1000 |

68-1832 |

19.5·10-6 |

10.8·10-6 |

WNR 1.4401 is resistant to rusting and corrosion, refer to INOX 316 material Thermal Conductivity.

WNR 1.4401 is renowned for its exceptional resistance to rust and corrosion. The molybdenum content significantly enhances its ability to withstand harsh conditions. For example, it can be used in chemical processing, marine, and offshore environments where protection against pitting and crevice corrosion is essential. Therefore, it is commonly used in medical appliances, food processing, and other applications that require adherence to hygienic standards during prolonged exposure to corrosive environments.

Thermal Conductivity of SS 1.4401

| Temperature Range |

Coefficients |

| °C |

°F |

W/m·K |

Btu/(hr/ft²/hr/°F/ft) |

| 20-100 |

68-212 |

14.6 |

100.8 |

INOX 316 Specific Heat

| Temperature Range |

J/kg·K |

Btu/lb/°F |

| °C |

°F |

| 20 |

68 |

450 |

0.108 |

| 93 |

200 |

450 |

0.116 |

Alloy 316 Magnetic Permeability

| Magnetic Permeability |

1.02 Max @ 200 H (H/m annealed) |

X5CrNiMo17-12-2 is widely used in high-corrosion and high-temperature applications, view Electrical Resistivity of SUS 316 grade.

Due to its molybdenum content, it exhibits superior resistance to rust, chemicals, and extreme heat conditions. This property makes it ideal for harsh environments, allowing consumers to utilize this material in marine applications, chemical processing plants, and medical equipment.

The table below shows the electrical resistivity, which indicates how much SUS 316 grade resists electrical current. Compared to copper and aluminum, it has high resistivity. Lower resistivity means better electrical conductivity, so copper, with its low resistivity, is the primary material used for electrical purposes because of its excellent conductivity.

Electrical Resistivity of SS 316

| ELECTRICAL PROPERTIES |

METRIC |

| Electrical Resistivity |

7.2e-005 ohm-cm |

Forging of SUS 316

| Forging Temperature |

Above 925°C |

Alloy 316 grade has great creep strength, check machinability of 316 Stainless Steel.

It has excellent creep strength, meaning it can withstand extreme heat and continuous pressure without damage. This property makes it suitable for applications exposed to extreme heat and pressure over long periods, such as industrial equipment, medical instruments, and offshore applications.

The machinability of SS 316 material is 60%, indicating that it is slightly more challenging to machine compared to materials with 100% machinability. It does not have the best machinability characteristics compared to free-machining alloys.

Special shaping tools are required, and slower speeds are necessary during machining. Consequently, its machining costs are higher, and the process is more complex. The hardness and tendency to work-harden can lead to shorter tool life and increased machining time, affecting production efficiency.

Machinability of X5CrNiMo17-12-2

Machinability of SS 316 Material is 60%

Weldability of UNS S31600

- GTAW (Gas Tungsten Arc Welding)

- TIG (Tungsten Inert Gas)

- GMAW (Gas Metal Arc Welding)

- MIG (Metal Inert Gas)

- MAG (Metal Active Gas)

- MMAW (Manual Metal Arc Welding)

- SAW (Submerged Arc Welding)

316 Stainless Steel Heat Treatment

| Working Temperature |

1868 ºF to 2012 ºF |

| Processing Information |

Cool Down: Air (<2mm); Water (>2mm) |

ASTM Standards of EN 1.4401 Grade

| Standard |

Description |

| ASTM A182 |

Flanges, Forged Fittings and Valves |

| ASTM A240 |

Sheet and Plate |

| ASTM A249 |

Boilers, Superheaters, Heat Exchangers |

| ASTM A276 |

Rods and Cross-sections |

Environmental Properties of BS 316S31 Material

| Medium |

Symbol |

Resistance |

| Flammability |

|

5 |

| Fresh Water |

|

5 |

| Organic Solvents |

|

5 |

| Strong Acid |

|

5 |

| Strong Alkalis |

|

5 |

| Weak Acid |

|

5 |

| Weak Alkalis |

|

5 |

Resistance Factors: 1 = Poor, 5 = Excellent

Why You Should Know the Density of AISI 316 Grade

- For weight calculations of products

- To estimate the cost of material

- To select the right material

- To predict the performance of material

UNS S31600 material has good formability and weldability properties, refer to SS 1.4401 grade operating temperature.

It is noted that the formability of UNS S31600 increases up to 300°C, and beyond this temperature, its formability decreases. According to the study, 300°C is the optimal temperature for deep-drawing.

Operating Temperature of WNR 1.4401

| Minimum Temperature |

-459.67 °F |

| Maximum Temperature |

1696.73 °F |

Is the 316 SS Material Magnetic?

| Magnetic |

No, not regularly |

Is the SS 1.4401 Material Polishable?

| Polishable |

Yes, it can be polished very well |

Yield and Tensile Strength of INOX 316 Grade

| Material Temperature |

1% Yield Strength |

Tensile Strength |

| Rp 1.0 |

Rm |

| 100 / 212 °C/°F |

>= 199 / >= 28.9 N / mm² / ksi |

430 / 62.4 N / mm² / ksi |

| 200 / 392 °C/°F |

>= 167 / >= 24.2 N / mm² / ksi |

390 / 56.6 N / mm² / ksi |

| 300 / 572 °C/°F |

>= 145 / >= 21.0 N / mm² / ksi |

380 / 55.1 N / mm² / ksi |

| 400 / 752 °C/°F |

>= 135 / >= 19.6 N / mm² / ksi |

380 / 55.1 N / mm² / ksi |

| 500 / 932 °C/°F |

>= 128 / >= 18.6 N / mm² / ksi |

360 / 52.2 N / mm² / ksi |

SS 316 VS 316L

| 316 Stainless Steel |

316L Stainless Steel |

| Contains up to 0.08% carbon |

Contains up to 0.03% carbon |

| Stronger and harder due to higher carbon content |

Less strong than SS 316 |

| Risk of forming carbide precipitation is higher |

Risk of forming carbide precipitation is lower |

The provided text now includes additional details and explanations, making it more comprehensive and readable.

Fermenting Equipment

Wenzhou Deli Machinery Equipment Co., Ltd. , https://www.sungoodtech.com