Molds have completely transformed the manufacturing landscape by allowing suppliers to efficiently produce identical parts at scale. Among the various molding techniques, injection molding stands out as a dominant method, particularly in sectors like automotive, aerospace, industrial machinery, and healthcare. In injection molding, molten plastic is injected into a mold to form a desired component. This process can be subdivided into two main categories: insert molding and overmolding.

### What is Insert Molding?

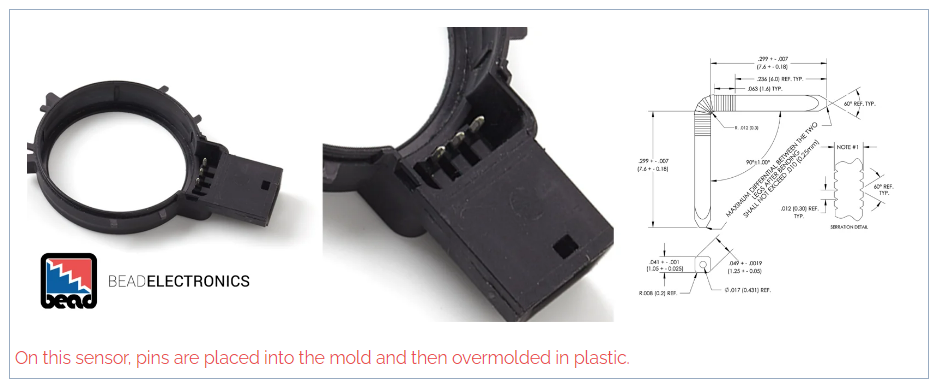

Insert molding is a manufacturing process where pre-formed components, often made of metal or other materials, are placed within a mold before injecting molten plastic. The result is a single, cohesive part that combines the strengths of both materials. For instance, threaded inserts are commonly integrated into fasteners, while metal contact pins are often used in electrical connectors.

This approach not only cuts down on the cost of individual parts but also eliminates the need for subsequent assembly, leading to significant cost savings. By blending the lightweight benefits of plastic with the robustness of metal, insert molding helps create durable, multifunctional products. However, if the inserts are custom-designed rather than standard parts, this might increase the time and expense involved in production.

#### When to Use Insert Molding

Consider using insert molding when your product requires:

- A metal component.

- Threaded inserts.

- Embedded sub-assemblies, such as wires, electronic components, or circuit boards.

#### How to Implement Insert Molding

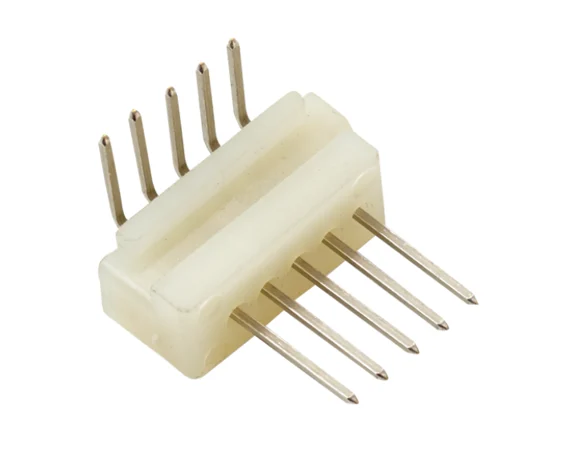

Insert molding opens up innovative possibilities in manufacturing. For example, components like right-angle pin headers can be mass-produced as sub-assemblies, making them easier to integrate into molds. This simplifies the process, reducing the need for manual placement of each individual component and cutting down on labor costs.

To fully leverage insert molding, ensure all necessary design files are prepared for engineers or designers to review. Your final design must incorporate insert CAD to assess how the inserts affect the product's structural integrity. Additionally, any design-for-manufacturability (DFM) considerations should be documented to evaluate product quality before production begins.

---

### What is Overmolding?

Overmolding is a specialized form of insert molding where a second layer of plastic is molded over an already-formed component. The initial part is created in one mold and then transferred to a second mold for the overmolding step. This technique is frequently employed in creating handles, where a softer plastic is applied over a firmer base to enhance grip comfort.

By integrating multiple materials into a single component, overmolding reduces the need for assembly and eliminates reliance on adhesives or other bonding agents. This approach results in a product with enhanced functionality, offering diverse textures, colors, and properties. It's also valuable for embedding soft seals into products.

An example of overmolding is the creation of pin assemblies. Instead of inserting individual pins one by one, a single component with numerous pins can be manufactured, improving precision and efficiency.

#### When to Use Overmolding

Opt for overmolding when your application demands features such as:

- Different thermal or electrical properties.

- Shock absorption or vibration dampening.

- Multi-colored designs.

- Comfortable, non-slip grips.

- Embedded soft seals.

Overmolded parts can be further customized based on specific requirements. These components are highly durable, making them ideal for the automotive sector. For instance, contact pins can be overmolded with plastic or rubber and used in connectors for vehicle sensors, control units, or entertainment systems.

Deciding between insert molding and overmolding depends on your component's unique needs. While insert molding is typically more cost-effective and faster, overmolding becomes advantageous when you require a more complex, multi-material solution.

At Bead Electronics, we have extensive experience supplying pins for a wide range of applications across industries like automotive, telecommunications, aerospace, industrial machinery, and healthcare. Our contact pins are versatile and can be incorporated into insert-molded or overmolded connectors for power, signal, or electromechanical purposes.

For expert guidance tailored to your project, feel free to reach out to our specialists today!

Waterproof Motorcycle Bag

Waterproof motorcycle bag,Motorbike Saddle Bag,Motorcycle Accessory Bag,Motorcycle Duffel Bag

Langfang Jinzhao Sports Products Co., Ltd , https://www.jinzhaowenti.com