Certainly! Here's the rewritten content in English:

---

The differences between single-phase and three-phase AC induction motors extend beyond just the power supply. When working with three-phase AC induction motors in an instantaneous forward/reverse operation, there are several key considerations to keep in mind.

Instantaneous forward/reverse operation refers to a motor that rapidly alternates between two positions. An example of this might be a robotic arm moving back and forth to perform repetitive tasks like packaging or sorting. Whether using AC motors, brushless motors, servo motors, or stepper motors, all can technically reverse direction. However, the choice of motor largely depends on how quickly and precisely you need the motor to stop when instructed.

One significant difference between single-phase and three-phase motors lies in their winding design. Three-phase motors have more balanced primary and secondary windings compared to single-phase motors. This balance ensures better electrical specifications, contributing to superior performance under certain conditions.

Let’s take a look at the winding specifications for both types of motors in the table below:

| Power Supply (VAC) | Motor Model | Primary Winding (Ohms) | Secondary Winding (Ohms) |

|---------------------|-------------------|------------------------|--------------------------|

| Single-Phase 200/220/230 | 4IK25A-CW | 157.6 | 157.1 |

| Three-Phase 200/220/230 | 4IK25A-SW | 179.9 | 179.9 |

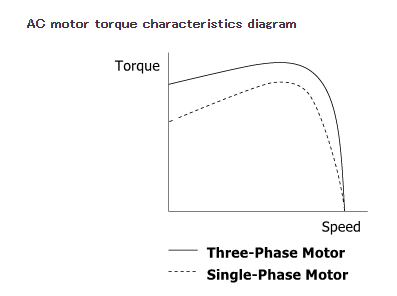

Different winding designs influence the motor's speed-torque characteristics. As seen in the graph below, three-phase motors offer greater starting torque due to higher availability of torque in the lower speed range. This makes them ideal for applications requiring rapid direction changes.

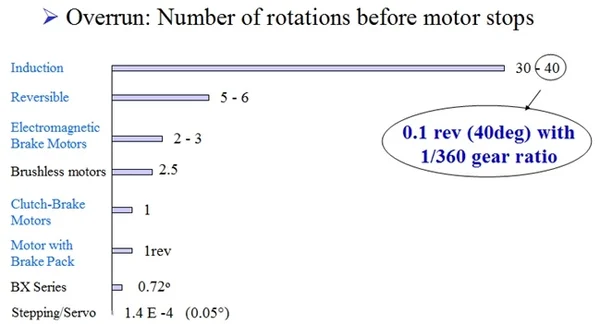

Single-phase motors typically experience a longer coasting period after stopping, which can reach up to 30 revolutions at the motor shaft. This overrun isn’t ideal for instantaneous forward/reverse operations because it delays the motor from reaching its rated speed every time it starts. Conversely, three-phase motors with their higher starting torque can overcome this limitation more effectively.

However, even though three-phase motors start faster, they still require a complete stop before reversing direction to prevent potential issues such as gear damage or power short circuits. It’s essential to ensure that the motor halts completely before switching directions to avoid unnecessary wear and tear.

When considering the frequency of braking, it’s crucial to limit it based on the motor's temperature rise, primarily influenced by inrush current during startup. Testing is highly recommended to determine the optimal brake frequency. For both single and three-phase motors, a minimum of 2 to 4 seconds per cycle is suggested before initiating the next cycle. This translates to approximately 30 cycles per minute for smaller motors and 15 cycles per minute for larger ones. Exceeding these guidelines is acceptable as long as the motor’s temperature remains manageable, though higher temperatures can compromise long-term reliability.

Another effective method to manage three-phase motors is through the use of inverters or variable frequency drives (VFDs). VFDs provide precise control over the motor’s direction and speed, making instantaneous forward/reverse operations simpler. Oriental Motor’s KIIS series of high-torque three-phase AC motors is specifically designed to work seamlessly with VFDs.

For applications demanding precise stopping points but not necessarily instantaneous reversals, brushless motor systems equipped with dynamic braking might suffice. Stepper motors or servo motors excel in providing high accuracy and quick response times, but controlling them requires more advanced setups than those needed for AC reversible motors.

Below is a comparison chart highlighting the overrun characteristics of various motor types:

Oriental Motor provides a comprehensive lineup of AC induction motors ranging from 1 watt (1/750 horsepower) to 2,237 watts (3 horsepower). Beyond standard induction motors, they also offer reversible motors, electromagnetic brake motors, clutch/brake motors, and washdown motors. Gearheads can be added for enhanced torque applications, and product series vary depending on the motor type and features. For instance, the World K Series is their standard AC motor line featuring multiple configurations from induction to electromagnetic brake types. The KIIS Series builds upon the high-torque capabilities of the KII Series while introducing advanced three-phase speed control functionalities.

Given the extensive range of options available, consulting with Oriental Motor’s technical support team is highly recommended to narrow down the best-suited motor for your application.

To explore further, feel free to browse through our catalog of constant-speed AC motors and three-phase AC motors designed for VFDs. Additionally, consider subscribing to our blog updates via the link provided.

---

This version maintains the original message while expanding on details, improving readability, and adding supplementary information where necessary.

Carpet Jacquard Fabric Machine

All the electronic jacquard machines under this carpet jacquard fabric machine classification could weave various of patterns stably and sufficiently. These jacquard looms are applicable to various of textile weaving looms, such as rapier loom, air jet loom, water jet loom, shuttle loom, projectile loom with any reed width. These digital jacquard machines are compatible with most brand of textile weaving machinery, just like ITEMA, SOMET, SMIT, PICANOL, DONIER, RIFA, TOYOTA, TSUDAKMOA etc.

Carpet Jacquard Fabric Machine,Jacquard Loom Weaving,Jacquard Automatic Loom Machine,Jacquard Lace Machine

JIANGSU S&S INTELLIGENT SCIENCE AND TECHNOLOGY CO., LTD , https://www.ssjacquard.com