For automated factories, motor failures can lead to significant production downtime and revenue loss. Identifying the specific issue and its location in advance is essential for maintaining operational efficiency. While adding extra sensors is a common solution, there might be a more efficient approach.

Using motor systems with built-in status monitoring capabilities can simplify the process for everyone involved. Monitoring various system statuses is the foundation of predictive maintenance, which helps identify potential problems before they escalate into actual failures.

| Challenge |

Monitor Your Machine Like a Traffic Light System |

Imagine a factory with dozens or even hundreds of such systems. Being able to detect potential issues early is crucial for keeping production running smoothly. So how does predictive maintenance work?

- Collect relevant data.

- Communicate the information effectively.

- Take action before a failure occurs.

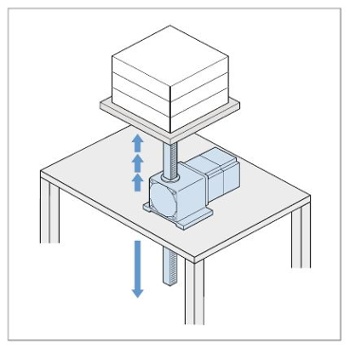

One example involves a motor with a rack and pinion mechanism that lifts and lowers a load. The key is to monitor critical parameters that affect the motor's performance and lifespan.

The first step is to determine what you want to monitor. Excessive load and heat are major threats to a motor's longevity. A motor’s life is often measured by the lifespan of its bearing grease, which is affected by operating temperature. For this example, we will focus on motor temperature as the most important factor.

Next, decide whether your motor driver needs communication capabilities. This will determine how you collect and transmit the data—through an industrial network, analog output, or digital I/O.

| TIP: Benefits of Networking |

|

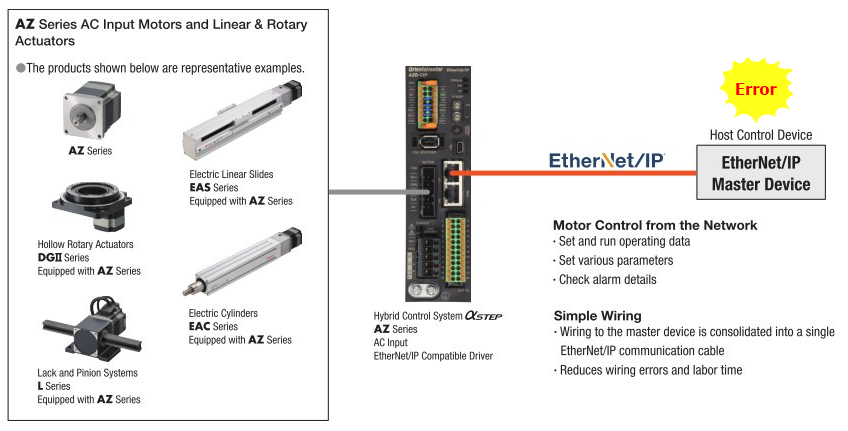

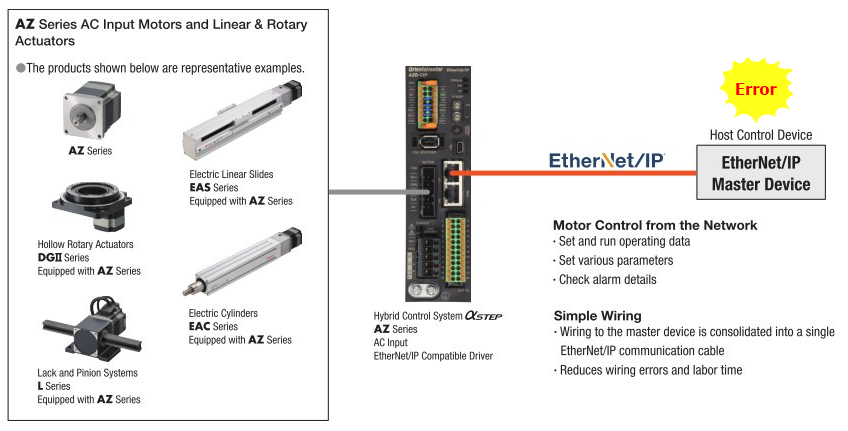

Minimizing time-consuming I/O wiring can be achieved by using an industrial communication network like EtherNet/IP or EtherCAT. This significantly reduces the number of wires needed between the master controller and the motor driver.

Setting up an industrial network allows access to more "remote" I/O, enabling the monitoring of additional variables. Examples include driver I/O status, motor position error, driver temperature, overvoltage, undervoltage, overload time, overspeed, cumulative load, tripmeter, odometer, RS-485 communication, homing, and other errors.

|

Once you’ve identified the variables to monitor, find the outputs that provide this data and connect them to your PLC, PAC, HMI, or any other monitoring system. Once connected, the status information can be continuously transmitted to the master via I/O or industrial network. You can set different thresholds based on your requirements.

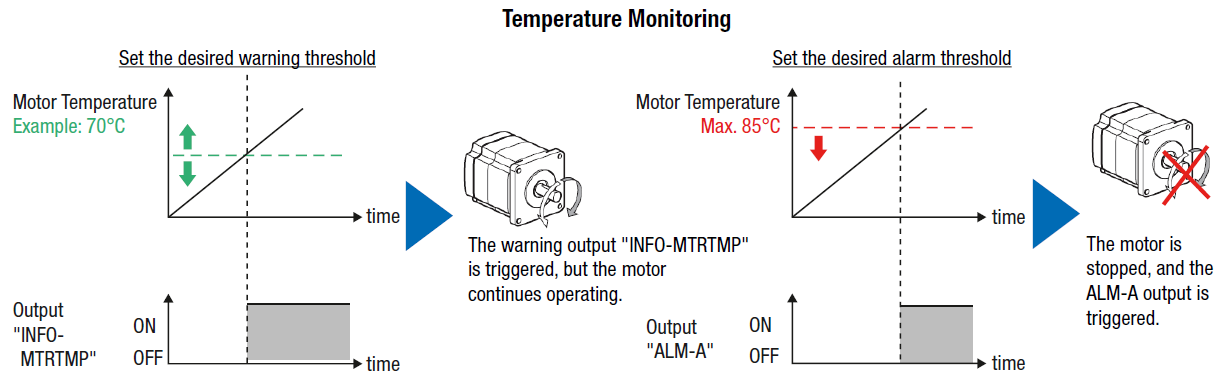

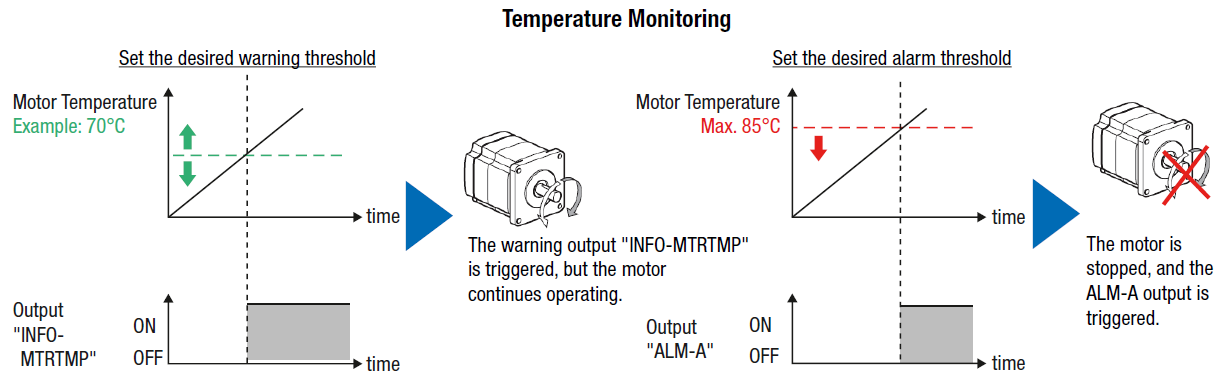

In the image below, we show how these “information†outputs function:

In this example, the INFO-MTRTMP output triggers when the motor’s temperature exceeds 70°C, while the ALM-A output triggers at 85°C. The difference is that when ALM-A activates, the motor stops automatically.

| TIP: What Is the Difference Between a Standard Output and an Information Output? |

|

This applies specifically to Oriental Motor products. A standard output is a default physical output assigned at the factory, while an information output is an optional one accessible through an industrial network or the MEXE02 software status monitor. INFO outputs provide warnings before an alarm triggers and the motor stops.

|

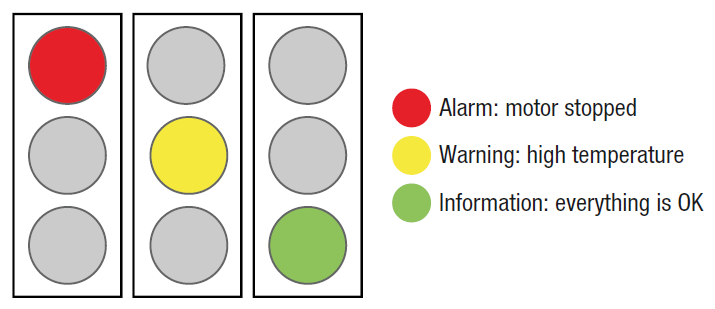

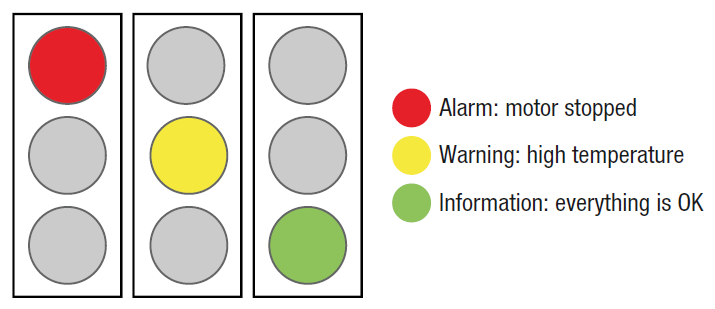

Now, how do we display this information to the operator? One effective way is to use a traffic light system, which is easy to understand and implement in our application example.

- GREEN - Everything is normal and the motor is operating correctly.

- YELLOW - INFO-MTRTEMP triggered, indicating temperature above 70°C.

- RED - ALM-A triggered, indicating temperature above 85°C.

Of course, a traffic light system may not be practical in all real-world scenarios. The key is to ensure the user understands the information quickly so action can be taken. How the information is displayed is ultimately up to the operator or programmer.

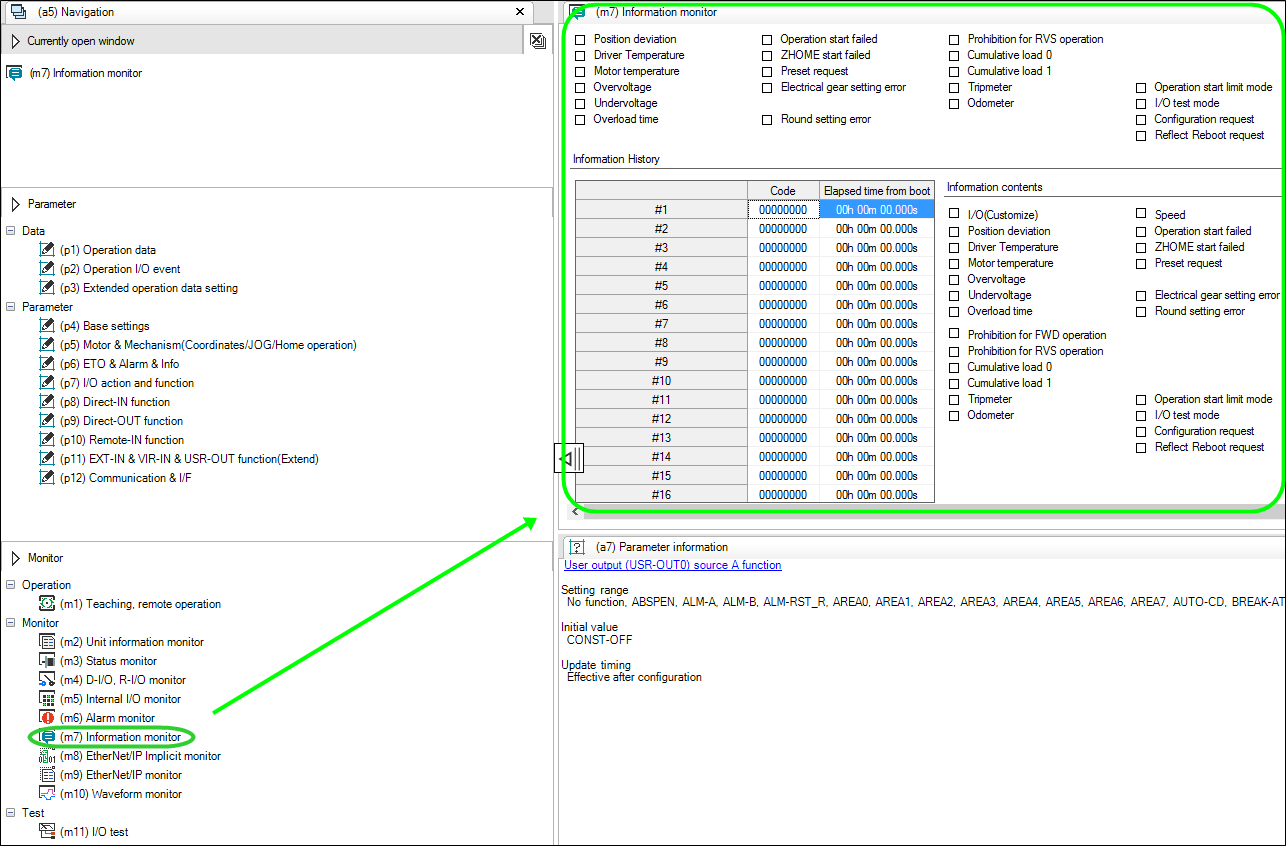

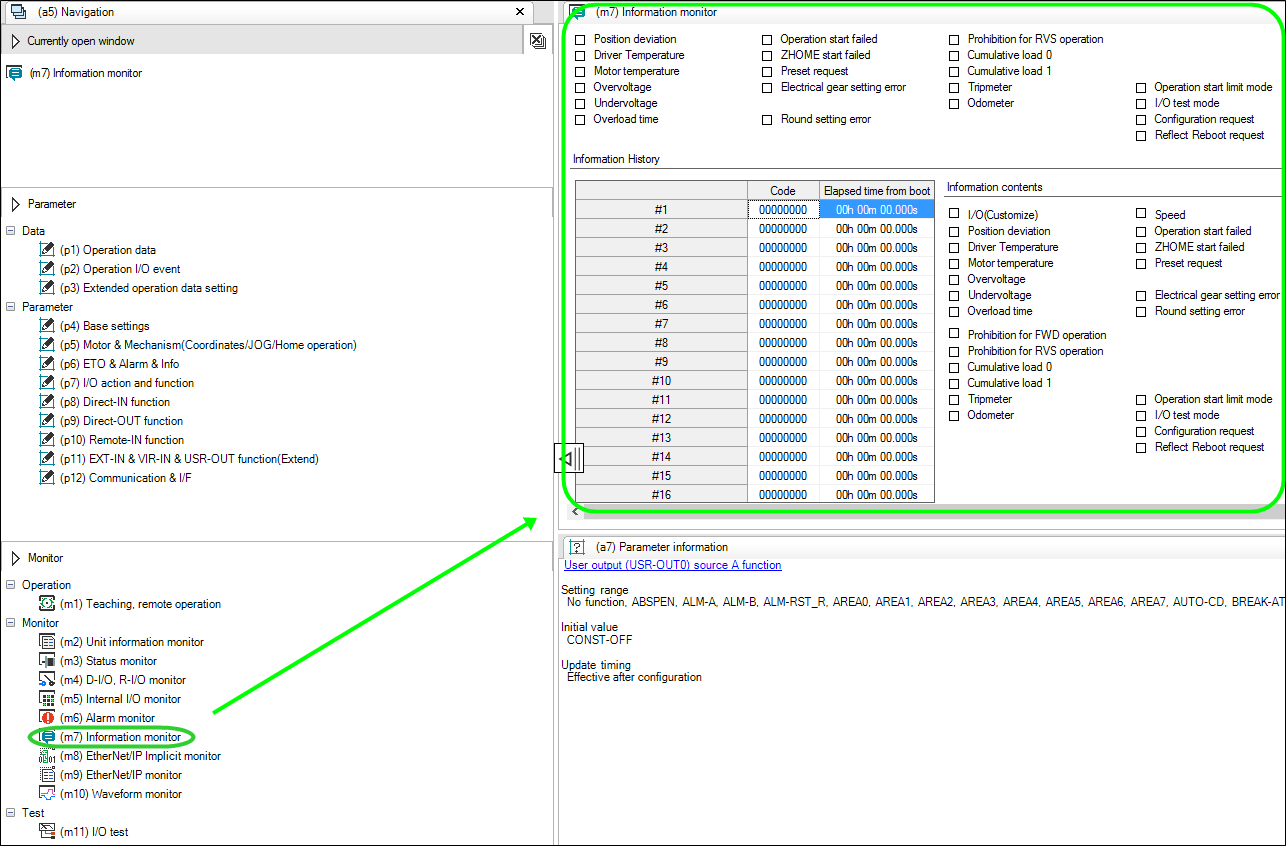

Another example uses the MEXE02 software to monitor these information outputs. This feature is accessed via the “Information Monitor.†While the software is designed for one motor at a time, factory operators can assign specific IDs to identify which motor axis is experiencing an issue.

When communication is established between the software and the driver, some boxes will be colored, while others remain blank. Make sure to click the check box to start monitoring.

To make all of this work efficiently, a driver with industrial communication capabilities is essential. These drivers offer more data than those without communication features, depending on what you need to monitor.

Oriental Motor offers EtherNet/IP and EtherCAT compatible drivers for the AZ Series stepper motors, rotary actuators, and linear motion systems.

| Solution |

AZ Series Network Type Drivers |

Here’s a video tutorial showing how to use an AOI to monitor motor status in Rockwell Automation’s Studio 5000 Logix Designer software (for Allen Bradley PLC users).

Thanks for reading! Subscribe to receive new posts and feel free to leave a comment if you have anything to add.

Related post:

Smart Heater

Smart heater means a heater with Wifi control by Phone.

Smart heaters inluding Fan Heater Wifi, Glass Panel Heater Wi-fi, Oil-filled heater Tuya, Wifi wall Silicate Panel Heater, Glass convection heater App.

Featuring a compact design, the Smart Heaters can be controlled from the heaters or connecting the smart wifi heater using Tuya's free mobile app to adjust settings from your hand. Monitors and manages the temperature in your home or office, set timers, or simply select the time of day you`d like to activate your Wifi heater.

Welcome to OEM smart heaters, we use Tuya app.

thanks

Smart Water Heater,Life Smart Heater,Wifi Heater,Smart Space Heater

Fenry Manufacturing Co., Ltd , https://www.cnfenry.com