How Are Parts Made Using Progressive Die Stamping?

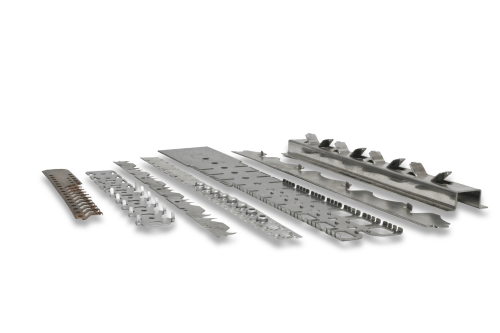

Progressive die stamping is a highly efficient manufacturing process that involves feeding a continuous strip of metal through a series of workstations. Each station performs specific operations—such as cutting, bending, and forming—to gradually shape the material into complex, durable components. This method is widely used across industries due to its ability to produce high volumes of parts with consistent quality and precision.

Understanding the Progressive Die Stamping Process

The progressive die stamping process typically consists of four key stages:

- A progressive die is installed in a stamping press, ensuring it can open and close properly during operation.

- The metal strip is fed through the die, where each press stroke performs precise blanking and forming actions. Some dies automatically remove excess material, enhancing automation and efficiency.

- The strip advances to the next station, where additional processes are applied progressively to achieve the desired design.

- At the final station, the finished part is separated from the strip for further processing or assembly.

Explore our in-house tool and die manufacturing capabilities

How Parts Are Made with Precision

Every stage of the progressive die stamping process is designed to meet ultra-high tolerance standards, ensuring consistent quality and performance in the final product.

Stock Strip Layout & Design

Before production begins, engineers use advanced computational models to design the progressive die. These models help optimize the placement of punches, bends, and holes on the metal strip, ensuring maximum efficiency and accuracy.

Tool Steel and Die Set Machining

Once the design is finalized, CNC machining is used to create the die blocks according to exact specifications. These components undergo rigorous quality checks to ensure they meet the required tolerances and durability standards before being used in production.

Secondary Processing: Grinding & Heat Treating

To enhance strength and stability, parts undergo heat treatment, which raises the temperature above the alloy’s critical transformation point. After rapid cooling, the parts gain improved durability and dimensional accuracy. Additional grinding may be applied for even tighter tolerances and superior surface finish.

Wire EDM

Wire Electrical Discharge Machining (EDM) is used to shape the die blocks with extreme precision. A charged brass wire cuts through the material using controlled sparks, achieving tolerances as tight as ±2 µm and surface finishes as smooth as Ra 0.1 µm.

Die Assembly

After all components are machined and tested, the die is assembled by skilled engineers using precision instruments to ensure it matches the original design specifications.

Stamping the Parts

The completed die is installed in a stamping press, where the metal strip is guided through each station. With every press stroke, the metal is cut, punched, and bent into the final form, completing the manufacturing cycle efficiently and accurately.

Packaging and Shipping

Once the parts are produced, they are packaged using automated systems that ensure accurate counts, weights, and secure delivery. This step ensures that orders are fulfilled efficiently and reliably.

Industries That Benefit from Progressive Die Stamping

Progressive die stamping is essential in many industries, including automotive, medical, appliance, and plumbing. The process enables mass production of high-quality, durable parts at high speeds, making it ideal for large-scale manufacturing needs.

Read More: Progressive vs. Fourslide vs. Traditional Power Press Stamping

At ESI, we’ve helped numerous clients improve their manufacturing processes through innovative solutions. Here are some examples of successful projects:

- Aqua Lung SCUBA Diving Part – We reduced material waste significantly, improving both cost-efficiency and quality. Our “D-ring†solution was crucial for a diving vest and made the product more affordable for our client.

- Seismic Cable Restraints – In just eight weeks, we manufactured 20,000 safety-critical cable restraints, enhancing their finish and reliability.

- Pre-Plated Cover Plate for Push-Button Lock – By increasing process consistency, we achieved an impressive 0.002-inch tolerance, saving our client $70,000 annually.

ESI’s Progressive Die Stamping Services

With over 30 years of experience, ESI has remained a leader in metal stamping, assembly, and mission-critical component manufacturing. We continuously invest in new technologies to improve quality and reduce costs for our customers. Whether you need custom tooling or high-volume production, we’re here to help. Contact us today or request a quote to learn more about how we can support your project.

Tractor is a self-propelled power machine used to pull and drive working machinery to complete various mobile operations.It can also be used as a fixed working power.It is composed of systems or devices such as engine, transmission, walking, steering, hydraulic suspension, power output, electrical instruments, driving control and traction.The power of the engine is transmitted to the driving wheels by the transmission system to make the tractor drive. In real life, rubber belts are commonly used as the medium of power transmission.Agricultural, industrial and special-purpose tractors are classified according to function and purpose; wheeled, crawler, boat-shaped tractors and self-propelled chassis are classified according to structure type.

The tractor's durability and engine power make it best suited for engineering tasks.Some engineering tools are often installed on tractors, such as bulldozers, dozer blades, reloading equipment, buckets, farming equipment, harvesters, etc.Bulldozers and buckets are often mounted on the front of the tractor. After the tractor is equipped with engineering tools, it is usually named an engineering vehicle.Bulldozers are usually track-type tractors with a blade in the front and a rope winch in the rear.Bulldozers are very powerful tractors with excellent contact with the ground, whose main task is to push or pull things.Dozers are constantly evolving, with new products and features that were not previously available on tractors.An example is the loader, which replaces the original blade with a large bucket and uses hydraulic arms to raise or lower the bucket, so it is easy to scoop up dirt, rocks and loose materials and load them onto the truck.Front-loading loaders and loaders are tractors with engineering tools, with two hydraulically powered arms mounted on either side of the front cabin; there is also a dumping device, which is actually a bucket with a larger opening, and some What is installed is a flat fork or a baler.

Farm Tractor,Electric Tractor,Compact Tractor,Farm Tractors

Shandong Vio Machinery co.,ltd. , https://www.shantui-xcmgparts.com

Comments are closed